Integrated PLC+HMI controller improves the portability and ease-of-use for reverse osmosis machine

Summary: Mar Cor Purification, Inc. specializes in manufacturing pure water and disinfection products for the medical, pharmaceutical and other life science industries. In order to develop a portable reverse osmosis water purification system—an important development for at home dialysis systems—they needed a compact, user friendly PLC to automate the purification and sanitization process. Mar Cor selected the Unitronics Vision570 PLC with integrated 5.7-inch color touch HMI for its reliability, compact design and easy communication features.

Mar Cor Purification offers products and solutions for not only water purification, but also dialysis, disinfecting and filtration systems. Mar Cor requires impeccable quality and consistency in all their solutions to be able to meet and exceed their customers’ exacting standards.

Mar Cor also seeks to offer new innovations and to consistently improve their processes whenever possible. For example they developed a heat-sanitizable, portable reverse osmosis system for the medical industry; their goal was to create a reliable water purification system that was easy to use and move in home and acute dialysis settings. In order to achieve this goal, Mar Cor required a compact control circuit and a user-friendly interface. They also wanted Ethernet communications and data logging features.

“The development process went a lot smoother due to the operator interface and PLC as one, and being programmed as one simultaneously…There are no annoying hurdles to jump, no additional communications software, communications hardware, or support costs. There is no burdensome software over protection getting in the way—just layout a design and build away!”

While testing various competing brands of electronics, Mar Cor was introduced to Unitronics all-in-one PLC+HMI products. “The Unitronics product had many attractive standard features.” said Mar Cor R&D Engineer, Clint Hulme. “It became quickly apparent through testing that the Unitronics products offered more bang for the buck than other major leading brands, plus the VisiLogic software was relatively easy to master.”

While testing various competing brands of electronics, Mar Cor was introduced to Unitronics all-in-one PLC+HMI products. “The Unitronics product had many attractive standard features.” said Mar Cor R&D Engineer, Clint Hulme. “It became quickly apparent through testing that the Unitronics products offered more bang for the buck than other major leading brands, plus the VisiLogic software was relatively easy to master.”

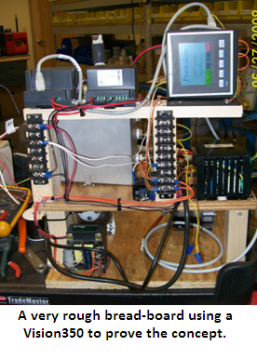

After some initial testing and prototyping using the Unitronics Vision350 programmable logic controller, Mar Cor settled on using theVision570, an advanced PLC with integrated 5.7-inch color touchscreen. Hulme explained that “the Vision570™ offers great flexibility in operator interface configuration in a size that nicely fits our devices dimensions, while still providing user readability.” The Vision570 provides 0-5 VDC control for pump speed, relay outputs for valve and heating element control, and discrete voltage inputs for safety switches, while analog voltage and current inputs were used for pressure, temperature, water quality. Mar Cor also logs critical data and used the PLC’s Ethernet communications to send the user this info via email.

“The Vision570™ programmable logic controller is a fantastic and feature rich product!” said Hulme. “The Unitronics support team is like having a personal, well versed friend on hand. The development process went a lot smoother due to the operator interface and PLC as one, and being programmed as one simultaneously. Application samples are numerous, and application specific advice is an email away. There are no annoying hurdles to jump, no additional communications software, communications hardware, or support costs. There is no burdensome software over protection getting in the way- just layout a design and build away!”