Why combine control and communications? It creates reliable automation that enables modern monitoring

Summary: AquaRD z.o.o. provides design and control solutions for the water and waste water industries. They specialize in innovative applications that provide flexible communication options, including with their own line of CellBox GPRS products. These solutions often use Unitronics PLC+HMI programmable controllers for responsive monitoring and control.

AquaRD z.o.o. operates in the water, waste water and sewage industries, offering solutions for the design, management, visualization, control and reporting of water management systems; one are of focus for AquaRD is creating innovative automated systems with their own GPRS product line, CellBox, integrated for wireless transmission capabilities. They often use Unitronics PLC+HMI controllers on their systems for reliable control and easy, comprehensive communications.

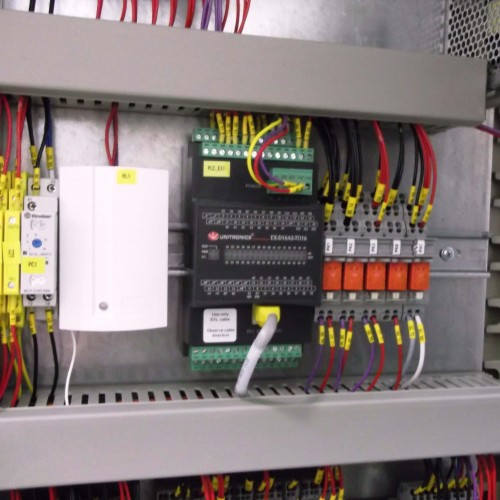

For example, AquaRD z.o.o. designed the control cabinet of a wastewater compressor station, using VisionV130 programmable logic controller (PLC+HMI). A hydrostatic probe measures the level of sewage and sends 4-20 mA signals to the controller; the value is processed and displayed on the operator panel. The PLC also compares the data to pre-assigned water levels, starting and stopping the pumps to keep the sewage in the tank at a required level. The Vision130 also alternates the operation of the pumps based on the programmed work time, or in case of to a failure, to ensure uniform wear on all the pumps. The compressor station can be set to run entirely automatically or in manual mode; operators can view key information about the pumps and compressor status on the integrated HMI panel.

“With a friendly development environment and unrivaled quality to price ratio, Unitronics PLC’s are the perfect solution – we highly recommend them!”

The Vision130 PLC also collects data from one of AquaRD’s GSM/GPRS modules, the CellBox-UxR. This allows the system to respond to events as they happen and display the changes in real time. If an alarm is triggered, the information is immediately sent a SCADA server where it is processed and presented in a variety of charts, graphs and reports. Some alarms will also send notifications via SMS messaging to ensure a speedy response.

The Vision130’s advanced communication options make it easy for AquaRD to monitor the compressor station remotely and respond quickly if any problems arise.

In addition to the standard alarms, triggered if the system is operating outside of programmed parameters, AquaRD programmed security features to prevent against user error. Firstly they set different access levels for authorized users; someone with operator clearance has read only access, while with service clearance they can both view and change settings from the operator panel. As an added security measure against unauthorized access to the control cabinet, AquaRD set the Vision130 to monitor the control cabinet’s hatch, triggering an alarm if it’s opened. This alarm can be disabled remotely to ensure easy access for authorized personnel.

AquaRD has had a lot of success using Unitronics PLC+HMI control systems. Michał Poniatowski says, “With a friendly development environment and unrivaled quality to price ratio, Unitronics PLC’s are the perfect solution – we highly recommend them!”